High-Grade Industrial Fan Experts

High-Grade Industrial Fan Experts

Manufacturer's Representative of High-Grade Industrial Fans

in Cleveland, OH

Powell & Associates has provided air make-up and ventilation solutions to Cleveland, OH, and the Northeastern Ohio area for over 60 years. We specialize in the heavy commercial and industrial markets and provide services from the initial system planning stages, all the way through product installation and startup, and post-sale maintenance and upgrading. Give us a call at (216) 261-0658 and let us exceed your expectations.

Powell & Associates has provided air make-up and ventilation solutions to Cleveland, OH, and the Northeastern Ohio area for over 60 years. We specialize in the heavy commercial and industrial markets and provide services from the initial system planning stages, all the way through product installation and startup, and post-sale maintenance and upgrading. Give us a call at (216) 261-0658 and let us exceed your expectations.

Manufacturer of High-Grade Industrial Fans in Euclid, OH

Powell & Associates has provided air make-up and ventilation solutions to Euclid, OH, and the Northeastern Ohio area for over 60 years. We specialize in the heavy commercial and industrial markets and provide services from the initial system planning stages, all the way through product installation and startup, and post-sale maintenance and upgrading. Give us a call at (216) 261-0658 and let us exceed your expectations.

What We Do

Powell & Associates has extensive knowledge and experience in most types of ventilation applications prevalent in the Industrial Sector and are familiar and comfortable working with a wide array of clients: engineering consulting firms; sheet metal fabricators; Plant Engineers, and Managers; as well as directly with the end-user, to name just a few.

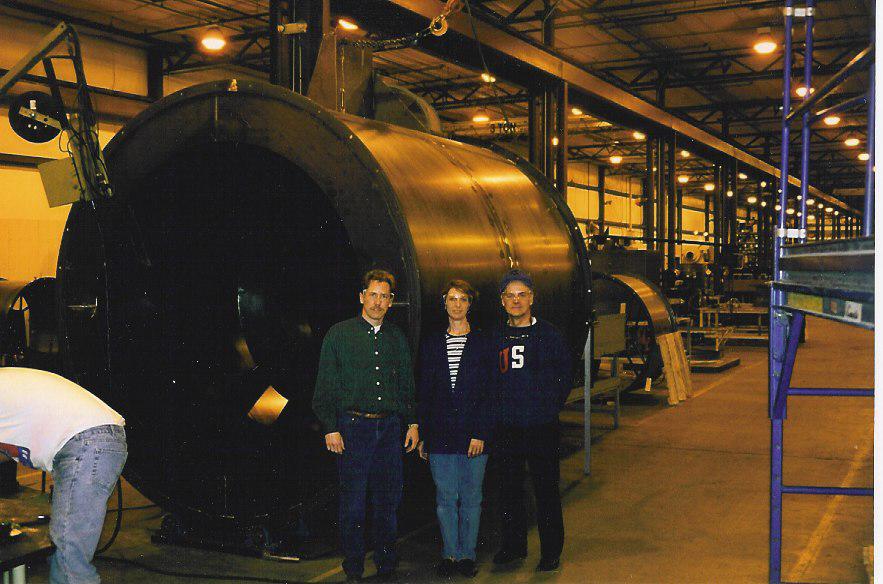

We Provide Aerovent Industrial Fans

We are experienced in providing consulting in all stages of the system design process. Whether just beginning to determine your general ventilation capacity requirements or whether acquiring detailed performance information of how specific Aerovent products will perform within your proposed system, we can help you each step of the way. In addition to system design services, we also provide services regarding pricing, installation, start-up, and post-sale maintenance and upgrading services.

Why Choose Powell & Associates

- 60 Years in Business

- Competitive Pricing

- High-Quality Products

- ISO 9001 Certified

What We Do

Powell & Associates has extensive knowledge and experience in most types of ventilation applications prevalent in the Industrial Sector and are familiar and comfortable working with a wide array of clients: engineering consulting firms; sheet metal fabricators; Plant Engineers, and Managers; as well as directly with the end-user, to name just a few.

We Provide Aerovent Industrial Fans

We are experienced in providing consulting in all stages of the system design process. Whether just beginning to determine your general ventilation capacity requirements or whether acquiring detailed performance information of how specific Aerovent products will perform within your proposed system, we can help you each step of the way. In addition to system design services, we also provide services regarding pricing, installation, start-up, and post-sale maintenance and upgrading services.

Why Choose Powell & Associates

- 60 Years in Business

- Competitive Pricing

- High-Quality Products

- ISO 9001 Certified

CONTACT INFORMATION

Phone: (216) 261-0658

Email: help@powellhvac.com

Address: 291 E 222nd St Suite 223 Euclid, OH, 44123

BUSINESS HOURS

- Mon - Fri

- -

- Sat - Sun

- Closed

CONTACT INFORMATION

Phone: (216) 261-0658

Email: help@powellhvac.com

Address: 291 E 222nd St Suite 223 Euclid, OH, 44123

BUSINESS HOURS

- Mon - Fri

- -

- Sat - Sun

- Closed